How to Choose a Carbon Fiber Bike Frame Manufacturer

Choosing the right carbon fiber bike frame manufacturer can feel overwhelming, especially with so many options available. You want a manufacturer who delivers high-quality materials, precise craftsmanship, and reliable production timelines. This guide will help you understand the key factors to consider, from materials and technology to certifications and customization options, so you can make a confident choice for your next carbon fiber bike frame.

What Defines a Reliable Carbon Fiber Bike Frame Manufacturer

Before diving into the specific qualities that make a manufacturer trustworthy, it helps to understand the key areas you should evaluate.

Consistent Quality and Materials

A reliable carbon fiber bike frame manufacturer ensures consistent quality in every frame it produces. You want a partner who carefully selects high-grade carbon fiber, like T700, T800, or T1000, and maintains strict quality control throughout the production process. Consistency in materials and workmanship means your frames will perform reliably ride after ride.

Core Manufacturing Technologies and Material Selection

To understand what makes a carbon fiber bike frame strong and reliable, it’s important to look at the manufacturing technologies and materials used.

High-Grade Carbon Fiber Materials

The quality of the carbon fiber itself plays a major role in the frame’s performance. Manufacturers often use T700, T800, or higher-grade fibers, which offer different balances of strength, stiffness, and weight. When you choose a manufacturer, make sure they clearly specify the type of carbon fiber used and its source.

Layup Techniques and Fiber Orientation

How the carbon fiber layers are arranged—called the layup process—directly affects the frame’s stiffness and durability. Skilled manufacturers carefully plan the fiber orientation to optimize strength in key areas while keeping weight low. Understanding their layup process can help you ensure the frames meet your performance expectations.

Molding and Curing Processes

Carbon fiber frames are shaped through molding techniques such as monocoque or tube-to-tube construction. The curing process, often done in high-temperature ovens, solidifies the resin and fibers into a strong, stable frame. Knowing how a manufacturer handles molding and curing gives insight into the overall quality control of the production process.

Material Testing and Quality Control

A reliable manufacturer tests materials at multiple stages, from raw carbon fiber to finished frames. These tests check for uniform strength, resin distribution, and defects. When you work with a manufacturer committed to quality, you can be confident in the safety and performance of every frame.

Key Factors to Consider When Choosing a Carbon Bike Frame Supplier

Choosing a supplier isn’t just about quality—it’s about how well they fit your business needs and long-term goals. By evaluating these strategic factors, you can select a partner who supports your growth and ensures smooth production.

Production Flexibility

You want a supplier who can adapt to changes in order volume, custom designs, or tight deadlines. Flexible production processes allow you to scale up or adjust specifications without delays or added complications.

Pricing and Cost Transparency

Understanding the supplier’s pricing structure is critical. Look for transparency in costs, including materials, labor, tooling, and shipping. A partner who is upfront about pricing helps you plan budgets accurately and avoid unexpected expenses.

Lead Times and Delivery Reliability

Timely delivery can make or break your production schedule. Evaluate whether the supplier consistently meets lead times and has contingency plans for unexpected delays. Reliable logistics and inventory management are key indicators of a dependable partner.

After-Sales Support

A strong supplier provides ongoing support after delivery. This includes handling minor defects, offering replacement parts, or assisting with technical questions. Knowing they are responsive after the sale gives you confidence in your partnership.

Collaboration and Communication Style

Choose a supplier who communicates clearly and collaborates openly. Regular updates, proactive problem-solving, and a willingness to listen to your requirements ensure a smooth working relationship and fewer misunderstandings.

By focusing on flexibility, cost transparency, delivery reliability, after-sales support, and communication, you can select a carbon bike frame supplier that not only meets your current needs but also grows with your business.

Evaluate the Manufacturer’s Experience and Quality

When choosing a carbon bike frame supplier, it’s essential to verify their experience and quality certifications. These two factors reveal a great deal about the reliability and consistency of their products.

Start by looking at how long they’ve been making carbon bike frames. A manufacturer with years of experience usually understands how to balance weight, stiffness, and comfort in a frame. They’ve likely tested different carbon layups, improved their molds, and refined the curing process to achieve stronger, more durable results.

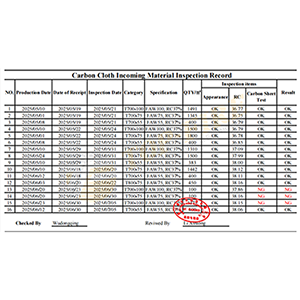

Next, pay attention to their quality certifications. Certifications like ISO 9001, EN testing, or SGS inspection show that the factory follows recognized quality control systems. This means every carbon frame goes through proper inspection, from raw material to final finish—before it reaches you.

Finally, look for transparency. Reliable suppliers are open about their production lines, testing methods, and customer feedback. They may even show fatigue test reports or in-house QC photos. When a supplier shares this kind of information willingly, it’s a good sign that they value quality and stand behind their carbon bike frames.

Comparing Carbon Frame Manufacturers: China vs. Europe

Here’s a clear comparison table showing the main differences between carbon frame manufacturers in China and Europe.

|

Aspect |

China Carbon Frame Manufacturers |

Europe Carbon Frame Manufacturers |

|

Production Cost |

Generally lower due to efficient mass production and optimized supply chains. |

Higher because of labor costs and stricter production standards. |

|

Technology Level |

Advanced composite technology with modern CNC molds and EPS forming. |

Focused on craftsmanship and precision, often with smaller production runs. |

|

Customization Options |

Wide range of OEM and ODM services, flexible mold design, and private labeling. |

Custom builds often tailored to premium brands or individual cyclists. |

|

Lead Time |

Shorter lead times and faster turnaround due to large-scale facilities. |

Longer production times because of smaller capacity and detailed handwork. |

|

Quality Control |

Uses automated inspection and international QC systems (ISO, SGS). |

Relies on manual inspection and reputation for European engineering. |

|

Pricing and Value |

Competitive pricing with a strong cost-performance ratio. |

Premium pricing, focused on brand heritage and exclusivity. |

|

Market Focus |

Global OEM supply for bike brands and startups. |

Niche market targeting high-end consumers and boutique brands. |

Previous :

Titanium Vs Carbon Road Bike FrameNext :

How To Choose Crank Arm LengthCategories

New Blog

Copyright © 2026 Top-Fire Carbon Technology Co., Ltd. All Rights Reserved. Power by

IPv6 network supported