The Key Benefits of Choosing Top-Fire Carbon Frames

|

Our carbon frames are designed to be incredibly lightweight yet durable. The carbon fiber material provides the perfect balance between strength and weight, improving both performance and handling for riders. Each Top-Fire carbon frame is produced with precision, using advanced carbon fiber manufacturing techniques. Our molding process ensures each frame is built for durability and strength. This high level of craftsmanship guarantees a reliable product for both professional and recreational cyclists. Top-Fire carbon bike frames are highly resistant to corrosion and damage, making them ideal for various weather conditions. Unlike metal frames, carbon fiber does not rust, and it retains its strength over time, ensuring a long-lasting investment for your business. In addition to performance, our carbon frames have an aesthetic appeal that enhances any bike's look. The sleek, polished finish reduces drag and improves aerodynamics, making your bike faster and more efficient on the road. |

|

Premium Carbon Fiber Materials

The first step in producing our carbon bike frames is selecting the best materials. We use high-quality carbon fiber sourced from trusted suppliers, ensuring exceptional strength and low weight. The carbon fibers we choose are known for their high tensile strength, which ensures that the frames are both durable and lightweight, ideal for riders looking for performance and longevity.

Precision Molding Process

Once we have the carbon fiber materials, we move to the precision molding phase. Using advanced molding techniques, we shape the carbon fibers into the required frame design. The molding process allows for a perfect balance between aerodynamics and strength, ensuring that each frame is optimized for both speed and durability. This step is critical in ensuring that the frame's geometry provides the best ride quality, whether on the road or off-road.

CNC Drilling and Finishing

After molding, the frames undergo CNC drilling for precise component fitments, such as the bottom bracket and headset areas. CNC technology ensures that these critical areas are drilled with utmost accuracy, providing the perfect fit for all parts. We then finish the frame with a high-quality sanding process, ensuring the surface is smooth and free from any imperfections that could affect the frame’s performance.

Resin Bonding and Layering

To ensure the carbon fibers are securely bonded together, we apply a high-pressure resin bonding technique. This process involves layering multiple sheets of carbon fiber with resin and applying pressure to cure them. The resin used is chosen for its superior bonding properties, ensuring that the frame is both rigid and flexible, absorbing shocks while maintaining structural integrity. This step is key to ensuring that the frame can withstand the forces it will encounter during cycling.

Rigorous Quality Control and Testing

After the frames are finished, they undergo a strict quality control process. We perform a series of stress tests, impact tests, and tensile strength tests to ensure that each frame meets the highest standards of quality and durability. Our quality assurance team checks every frame for defects and ensures it is free from any structural weaknesses. Only after passing these rigorous tests do the frames move on to the next stage.

To get a firsthand look at how we produce our carbon bike frames, watch the video below that takes you inside the Top-Fire production facility.

Consistent Manufacturing Standards

Our factory employs strict quality control processes at every stage of production. From precision molding to CNC drilling, each frame undergoes rigorous testing to ensure it meets the highest standards. This consistency and reliability make Top-Fire the preferred choice for global cycling brands that demand top-tier products.

Customization Options for Branding

Categories

New Products

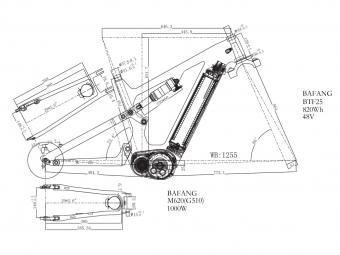

New Full Suspension Bafang M620 Motor Carbon Ebike Framest For MTB And Fat Bike Read More

Fully Internal Cable Routing Suspension Electric MTB Frame Read More

Carbon Gravel Ebike Frame With FSA Hub Motor And Battery Read More

Carbon Cyclocross Disc Gravel Bike Frame For BB T47 Read More

Top-Fire 27.5er 29er 27mm Width 25mm Depth Hookless Mtb Carbon Rims For XC Read More

New Style 700C Carbon Clincher Rims 58mm Depth Wavy Line Design Read More

Copyright © 2026 Top-Fire Carbon Technology Co., Ltd. All Rights Reserved. Power by

IPv6 network supported