Carbon Fiber vs Aluminum Alloy: Performance, Cost, and OEM Applications Compared

Speaking of bicycles, carbon fiber and aluminum alloy materials are currently the two most commonly encountered materials in bicycle manufacturing. For aluminum alloy materials, most people are familiar with them, and many people have not touched high-end carbon fiber materials. There is no concept of the strength comparison between the two. Customers often ask which aluminum alloy or carbon fiber is stronger. Let’s make a simple analysis.

What Is Carbon Fiber?

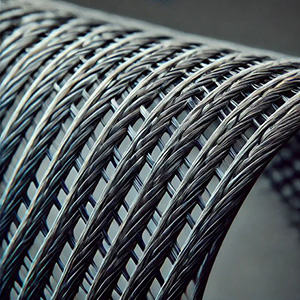

Carbon fiber is a high-performance material made of thin, strong fibers of carbon. It is lightweight yet incredibly stiff, which allows for excellent power transfer and precise handling in bicycles.

Properties and Performance Advantages

Carbon fiber offers an exceptional strength-to-weight ratio, making it ideal for components where every gram matters. It resists fatigue over time, maintains stiffness under stress, and can be molded into aerodynamic shapes. These qualities make it a top choice for competitive cycling and high-end bikes.

Applications in Bike Frames, Rims, and Wheelsets

You’ll find carbon fiber in bike frames, rims, and wheelsets. Its light weight improves acceleration and climbing, while the stiffness enhances stability at high speeds. Carbon fiber components also allow for innovative designs that are difficult to achieve with metals.

OEM and Bulk Manufacturing Benefits

For OEM buyers, carbon fiber enables customization and bulk production of specialized components. It supports branding differentiation and allows you to provide high-performance products to clients without compromising on durability or aesthetics.

What Is Aluminum Alloy?

Aluminum alloy is a lightweight metal commonly used in bicycle manufacturing and industrial applications. It offers a balance of strength, durability, and ease of production, making it a versatile choice for a wide range of uses.

Properties and Strengths

Aluminum alloys are known for being corrosion-resistant and relatively strong for their weight. While not as stiff as carbon fiber, aluminum can absorb shocks well, which is why it is often used for everyday bikes or components designed for durability.

Common Applications in Bikes and Industry

You’ll find aluminum alloy in bike frames, rims, and handlebars, as well as in automotive parts, machinery, and structural components. Its versatility allows it to meet the needs of both small-scale and industrial applications.

Cost-Effectiveness for Bulk Production

For OEM buyers and bulk orders, aluminum is particularly attractive. It is easier to machine, widely available, and more affordable than carbon fiber, which helps reduce production costs while maintaining reliability.

Carbon Fiber vs. Aluminum: Pros and Cons

When you compare aluminum alloy and carbon fiber, each material has clear advantages and trade-offs. Aluminum is affordable, widely available, and durable for everyday use. It is easy to manufacture in bulk, which makes it a practical choice for entry-level bikes, rims, and industrial components. Its main drawbacks are higher weight compared to carbon

fiber, low elasticity, and limited design flexibility.

Carbon fiber, on the other hand, is lightweight and extremely stiff. It excels in high-performance bike frames, rims, and wheelsets, allowing for precise handling and aerodynamic designs. For OEM buyers, it provides opportunities for brand differentiation and customized components. However, carbon fiber is more expensive due to its complex production

process, and it is brittle under excessive load. Scratches or internal damage can also reduce performance if not handled carefully. Understanding these pros and cons helps you choose the right material for both performance and production needs.

Carbon Fiber vs Aluminum: Weight and Strength Comparison

|

Property |

Aluminum Alloy |

Carbon Fiber |

|

Weight |

Lighter than steel, but heavier than carbon fiber |

Very light, ideal for high-performance bikes |

|

Strength |

Moderate, durable for everyday use |

High, excellent stiffness for precise handling |

|

Elasticity |

Low, prone to deformation under excessive force |

Low, stiff but brittle under overload |

|

Fatigue Resistance |

Good, can handle repeated stress |

Very good, maintains stiffness over time |

|

Durability |

Can bend but rarely breaks |

Can break if overloaded or scratched internally |

|

Cost |

Affordable, suitable for bulk production |

Expensive due to complex manufacturing |

|

Applications |

Entry-level bikes, rims, industrial parts |

High-performance frames, rims, and wheelsets |

Aluminum alloy materials have a wide range of applications in daily life. You can come into contact with this material in your life. The price of aluminum alloy is relatively cheap, the weight is lighter than steel, and the strength is higher. The disadvantage of this material is that it has poor elasticity and is prone to deformation after excessive force. Carbon

fiber materials are often used in combination with resins in applications. Carbon fiber composites are lighter in weight and have much higher strength than aluminum alloys. Due to the complex production process, the price is very expensive. The carbon fiber composite material has high hardness but is relatively brittle, and it will break if the load exceeds

the load limit. In addition, it will be damaged by scratching the inside, and the material performance will be greatly reduced.

Cost and Manufacturing Considerations

When choosing between carbon fiber and aluminum, understanding the differences in production processes and long-term costs is essential. These factors affect both your upfront investment and the performance of the final product.

Production Process Differences

To start, the way each material is manufactured is quite different. Aluminum alloy components are produced using casting, extrusion, or machining, which makes them straightforward and efficient for bulk production. Carbon fiber, however, requires layering fibers with resins and curing under heat and pressure. This complex process results in a

lightweight, stiff, and aerodynamic component, but it also demands specialized equipment and more production time.

Cost Implications for OEM and Bulk Orders

Understanding the manufacturing process leads directly to cost considerations. Aluminum’s simpler production and lower material cost make it more affordable for large OEM orders or bulk projects. Carbon fiber, while more expensive due to labor and materials, provides added value for high-performance or premium applications.

Long-Term Value of Carbon Fiber vs Aluminum

Finally, weighing the long-term benefits is crucial. While aluminum is durable for standard use, carbon fiber’s lightweight structure and stiffness improve efficiency, ride quality, and brand differentiation. For B2B buyers and OEM clients, these advantages can justify the higher upfront cost and support premium positioning in the market.

The Performance of Carbon Fiber Is Far Better Than that of Aluminum Alloy Materials

From the point of view of the compression or compression modulus of the material, the data of carbon fiber is 200 (GNm^ -2) and the data of 6 series aluminum alloy is between 69 and 79. The larger the data, the smaller the deformation under force and the higher the hardness.

Why B2B Buyers Choose Carbon Fiber

For B2B buyers and OEM clients, the decision to use carbon fiber goes beyond weight and strength. It involves performance, brand strategy, and flexibility in production. Understanding why this material is favored can help you make informed choices for your products.

Advantages for High-Performance Bike Frames and Wheelsets

First, carbon fiber provides unmatched performance benefits. Its lightweight and stiffness improve acceleration, climbing efficiency, and overall handling. High-performance bike frames, rims, and wheelsets made from carbon fiber allow your clients to achieve superior ride quality, which is critical for competitive cycling and premium product lines.

Applications in Industry and OEM Supply

Understanding where carbon fiber and aluminum materials are applied can help you make better sourcing and production decisions. These materials are versatile, serving both cycling and industrial needs, while offering flexibility for OEM buyers.

Cycling Components (Frames, Rims, Wheelsets)

In the cycling industry, carbon fiber is widely used for bike frames, rims, and wheelsets. Its lightweight and stiff properties enhance performance, making it ideal for racing bikes, high-end road bikes, and mountain bikes. Aluminum alloys are also used for durable, cost-effective components in entry-level or mid-range bicycles.

Industrial Equipment and Custom Components

Beyond bicycles, these materials are applied in industrial equipment, robotics, and custom machinery parts. Carbon fiber allows for complex shapes and precise tolerances, while aluminum provides strength at a lower cost. For B2B clients, selecting the right material depends on balancing performance, durability, and production efficiency.

Global OEM Supply and Bulk Order Capabilities

Both carbon fiber and aluminum are suitable for OEM production. Aluminum supports large-scale bulk orders, while carbon fiber enables customization for premium or niche products. Working with suppliers who can handle international logistics ensures timely delivery, consistent quality, and scalability for your business.

Conclusion

The difference between carbon fiber and aluminum alloy comes down to performance, weight, and application flexibility. The difference between carbon fiber and aluminum alloy is probably like this. Generally speaking, carbon fiber offers better strength-to-weight ratio, stiffness, and fatigue resistance, making it ideal for high-performance bike frames, rims, and wheelsets. Aluminum alloy, while slightly heavier and less stiff, remains a cost-effective and durable option for entry-level bikes, industrial components, and bulk OEM production.

For B2B buyers and OEM clients, choosing the right material involves balancing performance, cost, and long-term value. Moreover, the applications are quite extensive. Carbon fiber allows for premium designs, brand differentiation, and customized solutions, while aluminum provides reliable, scalable options for larger production runs.

Looking ahead, carbon fiber is expected to see growing adoption not only in cycling but also in industrial and construction applications. In the future construction industry, carbon fiber will surely become an industry with great development potential. Understanding these differences helps you make informed decisions for both current projects and future growth.

Categories

New Blog

Copyright © 2026 Top-Fire Carbon Technology Co., Ltd. All Rights Reserved. Power by

IPv6 network supported