Carbon Rim Production From Raw Carbon Fiber to Finished Rims

If you’ve ever wondered what makes a carbon road rim different from a regular wheel, you’re in the right place. Carbon rims are not just lightweight; they’re designed to improve speed, handling, and overall ride quality.

Here’s what you’ll learn in this guide:

How raw carbon fiber turns into a finished rim.

The key steps in design, molding, and finishing.

Quality checks that ensure safety and performance.

What is Carbon Fibre?

Carbon fiber is a lightweight, high-strength material made from thin bundles of carbon atoms. These filaments are about one-tenth the diameter of a human hair. These bundles are typically woven into sheets or combined with resin to create carbon fiber prepreg for manufacturing. Think of it as a "super material" because it combines incredibly lightweight with exceptional strength, two often conflicting properties.

There are different types of carbon fiber, such as T700 and T800, each offering unique stiffness and strength properties. Choosing the right type is key to producing high-performance carbon rims.

Here’s a simple overview of carbon fibre structure and its advantages:

|

Carbon Fibre Structure |

Description |

Key Advantages |

|

Single Fiber Strand |

Thin carbon atoms bonded into a fiber |

Lightweight, high tensile strength |

|

Fiber Bundle / Tow |

Multiple strands grouped together |

Easier handling, consistent prepreg |

|

Prepreg Sheets |

Fibers combined with resin |

Uniform strength, ready for molding |

|

Laminated Layers |

Multiple sheets layered in orientation |

High stiffness, directional strength |

|

Finished Carbon Rim |

Cured and machined rim |

Lightweight, durable, aerodynamic |

Key Features of Carbon Fiber Bicycle Rims

Lightweight Design: Reduces the overall weight of your bike, making climbing and acceleration easier.

High Stiffness: Transfers power efficiently from your pedals to the road, improving speed and responsiveness.

Durability: Resists fatigue and maintains performance over time, even under tough conditions.

Aerodynamic Profiles: Shaped to reduce wind resistance for smoother and faster rides.

Carbon Rims vs Aluminum Rims

|

Feature |

Carbon Fibre Rim |

Aluminum Rim |

|

Weight |

Very lightweight, easier climbing and acceleration |

Heavier, less efficient for speed |

|

Stiffness |

High stiffness for better power transfer |

Moderate stiffness, may flex under load |

|

Durability |

Long-lasting if properly maintained |

Can bend or crack more easily under stress |

|

Aerodynamics |

Can be shaped for optimized airflow |

Limited aerodynamic shaping |

|

Vibration Damping |

Absorbs road vibrations for smoother ride |

Transfers more vibrations to rider |

|

Customization |

Depth, width, and layup can be customized |

Fewer customization options |

Not all carbon fibers are the same. When selecting material for carbon rim production, you’ll encounter options like:

Each type has different mechanical properties, so it’s essential to choose one that aligns with the rim’s intended use and rider preference.

Preparation of Raw MaterialOrientation of fibers: Determines stiffness and strength in different directions.

Carbon Rim Design and Mold Preparation

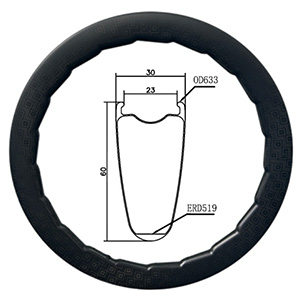

Design is a crucial step in carbon rim production. A well-planned design ensures that the finished rim is lightweight, stiff, and aerodynamic.

Rim Design Principles

When creating a carbon rim, you need to consider:

A precise CAD model is often used to simulate stress, airflow, and weight distribution. This helps ensure the final rim meets performance and safety standards.

Mold Preparation

Once the design is finalized, the mold must be prepared:

Cleaning and Polishing–Ensures smooth surfaces for the carbon layup.

Applying Release Agents–Prevents the rim from sticking to the mold.

Temperature and Pressure Calibration–Critical for consistent curing during molding.

Why This Step Matters

Proper design and mold preparation reduce errors during molding, improve rim performance, and allow for custom carbon road rims that meet both competitive and recreational riders’ needs.

Layup and Molding Process

The layup and molding process is where raw carbon fiber transforms into a high-performance rim. Attention to detail here determines the strength, stiffness, and durability of the final product.

Carbon Rim Manufacturing Process

Rim Finishing and Surface Treatment

After the rim is machined, the finishing and surface treatment stage ensures durability, safety, and performance.

Surface Preparation

During surface preparation, the rim is carefully sanded and polished to remove any minor imperfections. Special attention is given to the brake track to ensure reliable braking performance and long-term wear resistance. This step helps the rim perform consistently under different riding conditions.

Protective Coatings

Rims are often coated with protective layers to guard against UV exposure and scratches. These coatings maintain the rim’s finish over time and improve its durability. Custom graphics and logos can also be applied at this stage, which is especially important for OEM branding or personalization.

Why It Matters

Proper finishing and surface treatment are essential for producing road bike carbon rims that are both functional and visually appealing. A well-finished rim reduces wear, improves safety, and extends the rim’s lifespan, ensuring riders get the best performance from their investment.

Quality Control and Testing

Quality control is a critical step in carbon rim production. Every rim must meet strict standards before it reaches riders.

Visual Inspection

Each rim is first visually inspected for surface defects, scratches, or inconsistencies in the layup. This ensures that only rims meeting the highest standards move forward in the process.

Dimensional and Structural Testing

Rims are measured to confirm exact dimensions and tolerances. They undergo structural tests, including impact and fatigue tests, to verify stiffness, strength, and durability under real-world riding conditions.

Conclusion

Understanding the process behind carbon rim production provides a clear insight into what makes high-quality rims perform so well. From selecting the right carbon fiber prepreg to precise layup, molding, and finishing, every step contributes to the rim’s strength, stiffness, and durability.

By paying attention to material selection, design, and quality control, you ensure that your road bike carbon rims deliver consistent performance and reliability.

Whether you are a bike shop, brand, or rider, knowing how carbon rims are made helps you make informed choices and select rims that truly enhance the riding experience.

Explore our full range of carbon road rims to find options built with expert craftsmanship and high-performance materials.

Categories

New Blog

Copyright © 2026 Top-Fire Carbon Technology Co., Ltd. All Rights Reserved. Power by

IPv6 network supported