Top-Fire carbon cranks are designed for riders who value strength, lightness, and reliability. Designed for mountain bikes, road bikes, BMX bikes, and more, these carbon fiber cranks offer a precise balance of performance and durability. Each crank is crafted with high-quality carbon fiber to reduce weight while maintaining stiffness, making pedaling efficient and responsive. We offer a variety of lengths and can customize your size to suit a variety of bike types and rider preferences.

Item NO.:

170Order(MOQ):

10Payment:

Paypal, Bank Transfer, West UnionProduct Origin:

Xiamen,ChinaColor:

UD Matte/GlossyTop-Fire Premium Carbon Fiber Crank for MTB, Road & BMX

Carbon Crank Key Features

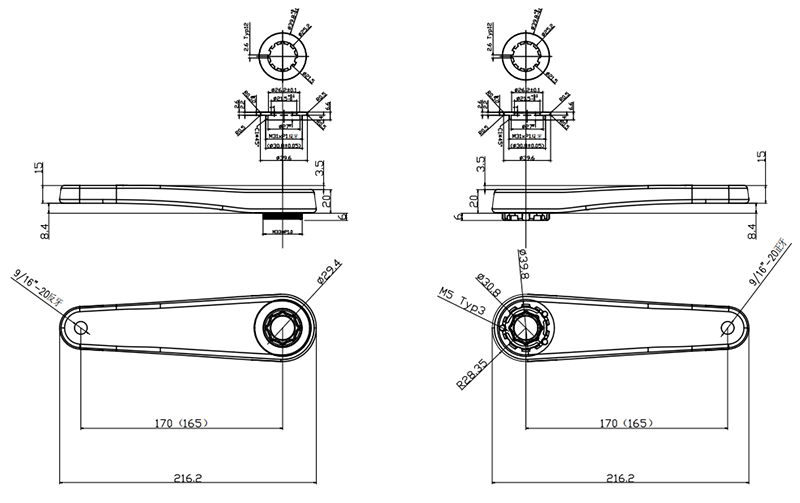

Carbon Bike Cranks Technical Specifications

Bottom bracket compatibility

Material

Carbon fiber

length

165mm/170mm

Compatible with most MTB, road, and BMX bottom brackets

Pedal Thread

Standard 9/16"-20

Overall Arm Length

216.2mm total

Best Carbon Cranks Applications

Carbon Road Cycling

Carbon cranks are perfect for road bikes. They are lightweight, which helps riders pedal easily over long distances. These cranks also improve power transfer, making each pedal stroke more efficient. Road cyclists can enjoy faster rides with less effort.

Carbon Mountain Biking

For mountain biking, durability matters. Carbon cranks can handle rough trails and jumps without bending or breaking. Their strength ensures reliable performance on rocky or uneven paths, while keeping the bike light for better control.

Gravel and Adventure Bikes

Gravel riding and adventure biking need cranks that are both strong and light. Carbon cranks help riders maintain speed on mixed surfaces, from dirt paths to paved roads. They also reduce fatigue on long rides.

Casual and Fitness Cycling

Even for casual riders or fitness enthusiasts, carbon cranks make a difference. They provide smoother pedaling and better efficiency, helping riders enjoy more comfortable rides on city streets or park trails.

Carbon cranks vs aluminum

Feature

Carbon Cranks

Aluminum Cranks

Weight

Very lightweight, reduces bike’s overall weight, ideal for road and gravel use

Heavier than carbon, but still lighter than steel cranks

Strength & Stiffness

High stiffness for efficient power transfer, handles road and MTB riding well

Strong, but less stiff; may flex slightly under heavy loads

Durability

Long-lasting with proper care; resistant to fatigue when maintained

Transfers more road shock to the rider

Comfort

Absorbs vibration better, offering smoother rides

Transfers more road shock to the rider

Price

Higher cost due to advanced carbon fiber materials

More affordable and widely available

Best Use

Performance cycling, climbing, racing, and long-distance rides

Everyday riding, budget builds, or riders who prioritize low cost

Carbon Bike Cranks Manufacturing Process

Material Selection

The process starts with high-quality carbon fiber sheets. These sheets are chosen for their strength and light weight. Using the right carbon fiber ensures the crank is durable but still easy to pedal.

Layering and Molding

Carbon fiber layers are carefully arranged and shaped in a mold. This step gives the crank its strong and precise structure. The layers are aligned to handle stress from pedaling and rough terrain.

Curing and Hardening

Once molded, the crank goes through a heating process called curing. This hardens the carbon fiber and resin, making the crank solid and reliable. Proper curing ensures long-lasting performance.

Finishing and Inspection

After curing, the crank is polished and finished for smooth surfaces. Each crank is inspected to make sure it meets strict quality standards. This step guarantees that every crank is safe, strong, and ready for use.

Final Assembly

Finally, the crank is prepared for installation with bearings and bolts. It is compatible with most bikes and designed for easy setup. This careful process results in a lightweight, strong, and efficient carbon bike crank.

Carbon Cranks Installation & Maintenance

Installation Steps

Installing carbon cranks is simple, but accuracy matters. Start by cleaning the bottom bracket to remove dust or old grease. Place the crank arms onto the spindle and make sure they sit flush. Then, tighten the bolts evenly using the torque values recommended by the manufacturer. A small layer of grease on the threads will keep them from seizing in the future.

Carbon cranks need only basic care to last long. After rides, check the bolts to make sure they are secure. Wipe the crank arms with a soft cloth to remove dirt and moisture. Inspect the surface for cracks or scratches, especially if you ride off-road.

FAQ

Q: Are carbon cranks reliable for long-term use?

A: Yes. A well-made carbon crankset offers excellent durability. With proper installation and care, carbon cranks can handle years of riding on road, gravel, or mountain bikes.

Q: Do I need special tools for carbon cranks installation?

A: Not always. Most carbon bike cranks use common tools, but it’s important to follow torque guidelines. Using the right torque prevents over-tightening, which protects the carbon layers from damage.

Q: What happens if a carbon crank gets scratched?

A: Small surface marks are usually cosmetic. However, deeper cracks should be inspected by a mechanic. Unlike aluminum, carbon damage is not always visible, so routine inspection helps maintain safety.

Q: Do carbon cranks wear out faster than aluminum?

A: Not necessarily. A lightweight carbon crankset is designed with strong fiber layers that resist fatigue over time. With normal riding and regular checks, they often last as long—or longer—than aluminum cranks.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

New Products

New Full Suspension Bafang M620 Motor Carbon Ebike Framest For MTB And Fat Bike Read More

Fully Internal Cable Routing Suspension Electric MTB Frame Read More

Carbon Gravel Ebike Frame With FSA Hub Motor And Battery Read More

Carbon Cyclocross Disc Gravel Bike Frame For BB T47 Read More

Top-Fire 27.5er 29er 27mm Width 25mm Depth Hookless Mtb Carbon Rims For XC Read More

New Style 700C Carbon Clincher Rims 58mm Depth Wavy Line Design Read More

Copyright © 2026 Top-Fire Carbon Technology Co., Ltd. All Rights Reserved. Power by

IPv6 network supported