The 700C Carbon Road Bicycle Rim features a 28mm width and 50mm depth, constructed from high-quality Toray T700 and T800 carbon fiber. Designed for cyclists who value lightweight performance, durability, and speed, these carbon road bike rims offer reliable quality for both professional and recreational riders. Our advanced manufacturing process ensures consistency, making every rim a trusted choice for all road cycling needs.

Item NO.:

CTR024Order(MOQ):

10Payment:

Paypal, Bank Transfer, West UnionProduct Origin:

Xiamen,ChinaColor:

UD/3K(Customized Painting Acceptable)700C Carbon Rims Road 28mm Width

Carbon Rims Road Bike Feature

Carbon Rims Road Specification

| Model | CTR024 |

| EDR | 539mm |

| OD | 633mm |

| Height | 50mm |

| Width | 28mm |

| Inner Width | 21mm |

| Weight | 420±15g / 390±10g |

| Material | Toray T700 + T800 Carbon Fibers |

| Toray T800 + T1000 Carbon Fibers | |

| Tire Compatibility | Clincher/ Tubeless |

| Rim Holes | 20/21/24 (Customization) |

| Recommended Tire Size | 25-28C |

| Brake Type | Disc Brake |

Why Choose Top-Fire Carbon Fiber Rims for Road Bike?

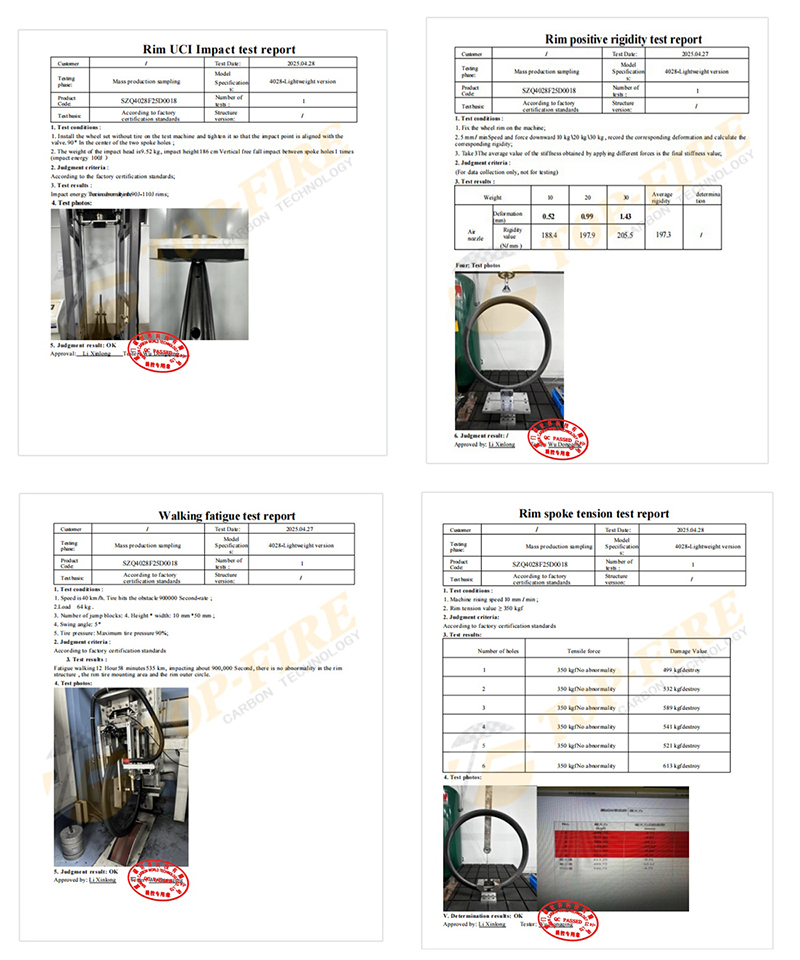

Performance Testing of Carbon Rims Road

Rim UCI Impact Test

This test simulates the impact a rim may face during extreme riding conditions. With the rim set up without spokes, a vertical free-fall impact is applied directly to the spoke hole area, in accordance with UCI standards.

Result: The rim withstood the repeated impacts without cracks or structural damage, fully meeting UCI certification requirements.

Rim Positive Rigidity Test

Rigidity testing evaluates how the rim responds when subjected to vertical loads. In this test, the rim was mounted on a machine and subjected to increasing loads of 10 kg, 20 kg, and 30 kg. The corresponding deformation was measured at each stage, and the stiffness values were calculated.

Result: The rim achieved an average rigidity of 197.3 N/mm. The rim maintained stable stiffness across different loads, ensuring excellent responsiveness and stability for high-performance riding.

Walking Fatigue Test

The walking fatigue test simulates long-term riding conditions to evaluate rim durability under repeated impact. In this test, the rim was run at a constant speed of 40 km/h while the tire struck obstacles measuring 10 mm in height and 50 mm in width. The setup included a load of 64 kg, a swing angle of 5°, and tire pressure at 90% of the maximum rating. Over the course of the test, the rim experienced approximately 900,000 continuous impacts.

Result: After 12 hours and 58 minutes of testing, covering a distance of 535 km, the rim showed no abnormalities in its structure, tire mounting area, or outer circle. These results confirm the rim’s outstanding fatigue resistance and reliability for long-term cycling performance.

Rim Spoke Tension Test

Spoke tension testing ensures the rim can handle high spoke pulling forces during wheel assembly and real riding conditions. The rim was tested at multiple spoke tension levels up to 500–600 kgf.

Result: The rim withstood high spoke tension without abnormalities, proving its reliability in heavy-load and competitive environments.

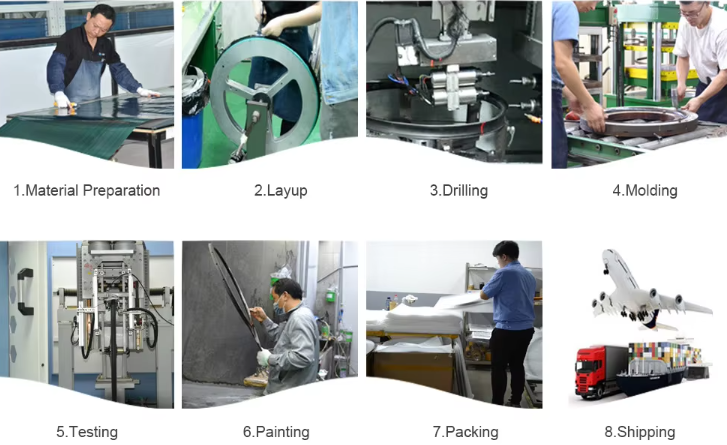

Carbon Fiber Road Bike Rims Manufacturing Technology

Material Preparation

The process begins with selecting premium carbon fiber sheets. Each sheet is inspected for consistency, thickness, and fiber alignment before being precisely cut to size. This step ensures the structural integrity and performance of the final wheel.

Lay Up

Cut carbon sheets are carefully layered into molds according to a specific layup schedule. The fiber orientation is strategically arranged to achieve optimal strength, stiffness, and weight balance. Skilled technicians ensure every layer is placed without wrinkles or gaps.

Drilling

After preliminary shaping, precision drilling machines create accurate spoke holes and valve holes. This step demands high accuracy to ensure perfect spoke alignment and long-term durability under riding stress.

Molding

The mold is closed and heated under pressure. This bonds the resin and fibers together, creating the rim’s solid structure. The layered carbon is placed into a high-temperature, high-pressure mold. This molding process compresses the fibers and cures the resin, forming the wheel’s final structure while maximizing strength and minimizing weight.

Testing

Each molded rim undergoes rigorous quality checks. Dimensional accuracy, roundness, and structural integrity are tested by load and impact tests to confirm safety and performance.

Painting

A protective coating or custom paint is applied, giving the wheel its final look and extra protection against the elements. After passing tests, rims enter the painting and finishing stage. Here, protective coatings and custom graphics are applied. This not only enhances the aesthetic appeal but also provides UV and weather resistance.

QC Test

Every rim undergoes strict dimensional, strength, and balance testing. Wheels are carefully packed using protective foam and custom-fit boxes to prevent any damage during transport. This ensures they arrive at customers in perfect condition.

Packing

Rims are securely packed to prevent damage during shipping. Wheels are carefully packed using protective foam and custom-fit boxes to prevent any damage during transport. This ensures they arrive at customers in perfect condition.

Shipping

Finished carbon road wheels are shipped worldwide via air, sea, or land logistics, ready to deliver top-tier performance to cyclists across the globe.

Carbon Fiber Rims Road Bike Customization

Top-Fire offers full carbon fiber rims road bike customization to meet the unique needs of riders and professional teams. Customers can choose rim width, depth, color, decals, and other design features to match their bike specifications. We also provide OEM services, allowing bulk orders with branding or specific technical requirements. With Top-Fire custom rims, cyclists can get a personalized, high-performance wheelset that combines style, functionality, and durability.

Key Customization Options:

Rim Width & Depth: Select the size that suits your riding style.

Color & Finish: Choose custom colors, graphics, and finishes.

Decals & Branding: Add logos or team designs for a unique look.

OEM Services: Professional bulk orders with tailored specifications.

Carbon Rims Road vs Aluminum Rims: Which One to Choose

When choosing wheels for your road bike, the material makes a big difference. Below is a clear comparison between carbon rims for road bike and traditional aluminum rims:

|

Feature |

Carbon Rims Road |

Aluminum Rims |

|

Weight |

Lighter, reduces overall bike weight for faster climbs and acceleration |

Heavier, can slow down performance on hills |

|

Stiffness |

High stiffness for better power transfer and responsive handling |

Moderate stiffness, less efficient power transfer |

|

Aerodynamics |

Optimized aerodynamic design for faster riding |

Average aerodynamics |

|

Durability |

Fatigue-resistant and impact-tested |

Less durable under repeated stress |

|

Braking Performance |

Reliable rim brake or disc brake compatibility |

Reliable but may heat faster under long descents |

|

Price |

Premium |

Lower, more affordable |

|

Riding Experience |

Smooth, precise, and fast |

Functional but less performance-oriented |

Top-Fire carbon rim road bike combine advanced materials, precision engineering, and rigorous quality control to deliver top-level performance for all cyclists. Each rim is lightweight yet strong, providing excellent stiffness, aerodynamic efficiency, and responsive handling. Whether you are racing, training, or enjoying long rides, Top-Fire carbon rims ensure improved speed, better control, and a smoother ride. Trusted by professional teams and enthusiasts worldwide, these rims offer reliability, durability, and an unmatched riding experience.

Key Advantages:

Premium Carbon Construction: Made from Toray T700 & T800 for strength and low weight.

Lightweight & Stiff: Optimized for faster acceleration and precise power transfer.

Aerodynamic Design: Enhances speed and reduces wind resistance.

Durable & Reliable: Fatigue-tested for long-lasting performance.

Trusted Brand: Preferred by professional cyclists and competitive teams.

Read More For Production Of Carbon Rims By Top-Fire Factory

Read More For Testing Of Carbon Rims By Top-Fire Factory

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

New Full Suspension Bafang M620 Motor Carbon Ebike Framest For MTB And Fat Bike Read More

Fully Internal Cable Routing Suspension Electric MTB Frame Read More

Carbon Gravel Ebike Frame With FSA Hub Motor And Battery Read More

Carbon Cyclocross Disc Gravel Bike Frame For BB T47 Read More

Top-Fire 27.5er 29er 27mm Width 25mm Depth Hookless Mtb Carbon Rims For XC Read More

New Style 700C Carbon Clincher Rims 58mm Depth Wavy Line Design Read More

Copyright © 2026 Top-Fire Carbon Technology Co., Ltd. All Rights Reserved. Power by

IPv6 network supported