The Top-Fire Lightweight Hub carbon road bike wheels are crafted using high-quality Toray T700 and T800 carbon fiber. With a depth of 45mm and a height of 28mm, the front wheel weighs 539.5 grams, while the rear wheel weighs 645 grams. These wheels are designed for optimal aerodynamics and speed, making them an excellent choice for serious cyclists. ensuring a light, responsive ride.

Item NO.:

R4528SLPayment:

Paypal, Bank Transfer, West UnionProduct Origin:

Xiamen,ChinaColor:

UD/3K/12K(Customized Painting Acceptable)Shipping Port:

XIAMENTop-Fire 700C Fastest Carbon Road Bike Wheels

Key Features of Top-Fire 700C Carbon Road Wheels

*All of our carbon road rims fit this lightweight hub.

Carbon Road Wheels Specification

Model

R4528SL

Weight

Front Wheel Weight: 539.5g

Rear Wheel Weight: 645g

Rim Size

Drills: 20/20 Holes

Outer Width: 28mm

Inner Width: 21mm

Tire Compatibility

Clincher/ Tubeless

Recommended Tire Size

25-28C

Chossen Hub

RD240

Perrin:Ceramics

Freehub Body:Planetary gear(Shimano)

spacing:Front: 12*100 mm Rear:12*142mm

Spoke Count

Front: 20 Rear:20

Spoke Pattern

Front: 2X 1:1 Rear: 2X 1:1

Max Spoke Tension

>450kgf

Rim Material

Toray T700 + T800 Carbon Fibers

Spoke Material

Carbon Fiber

Disc brake/rim brake

Disc brake

Warranty

18 months

Packing Size

850*650*200mm(Carton)

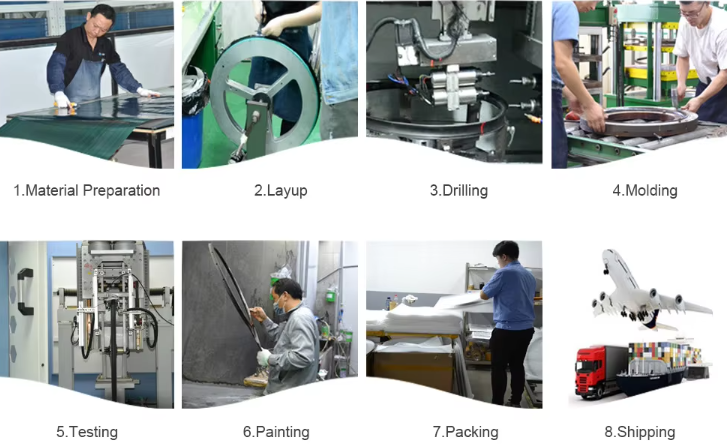

Carbon Fiber Wheels for Road Bikes Manufacturing Process

Material Preparation

The process begins with selecting premium carbon fiber sheets. Each sheet is inspected for consistency, thickness, and fiber alignment before being precisely cut to size. This step ensures the structural integrity and performance of the final wheel.

Lay Up

Cut carbon sheets are carefully layered into molds according to a specific layup schedule. The fiber orientation is strategically arranged to achieve optimal strength, stiffness, and weight balance. Skilled technicians ensure every layer is placed without wrinkles or gaps.

Drilling

After preliminary shaping, precision drilling machines create accurate spoke holes and valve holes. This step demands high accuracy to ensure perfect spoke alignment and long-term durability under riding stress.

Molding

The mold is closed and heated under pressure. This bonds the resin and fibers together, creating the rim’s solid structure. The layered carbon is placed into a high-temperature, high-pressure mold. This molding process compresses the fibers and cures the resin, forming the wheel’s final structure while maximizing strength and minimizing weight.

Testing

Each molded rim undergoes rigorous quality checks. Dimensional accuracy, roundness, and structural integrity are tested by load and impact tests to confirm safety and performance.

Painting

A protective coating or custom paint is applied, giving the wheel its final look and extra protection against the elements. After passing tests, rims enter the painting and finishing stage. Here, protective coatings and custom graphics are applied. This not only enhances the aesthetic appeal but also provides UV and weather resistance.

QC Test

Every rim undergoes strict dimensional, strength, and balance testing. Wheels are carefully packed using protective foam and custom-fit boxes to prevent any damage during transport. This ensures they arrive at customers in perfect condition.

Packing

Rims are securely packed to prevent damage during shipping. Wheels are carefully packed using protective foam and custom-fit boxes to prevent any damage during transport. This ensures they arrive at customers in perfect condition.

Shipping

Finished carbon road wheels are shipped worldwide via air, sea, or land logistics, ready to deliver top-tier performance to cyclists across the globe.

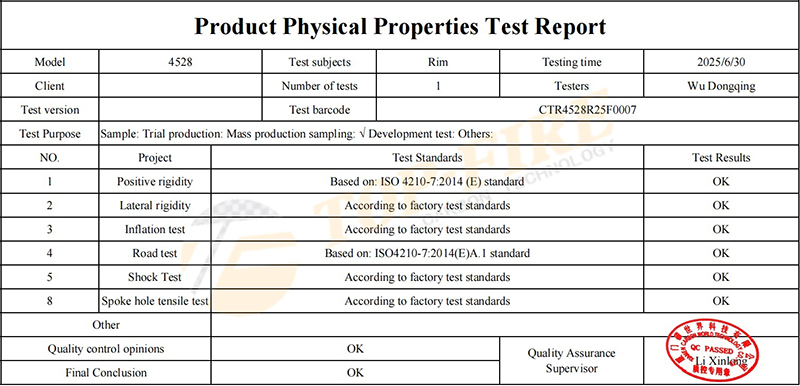

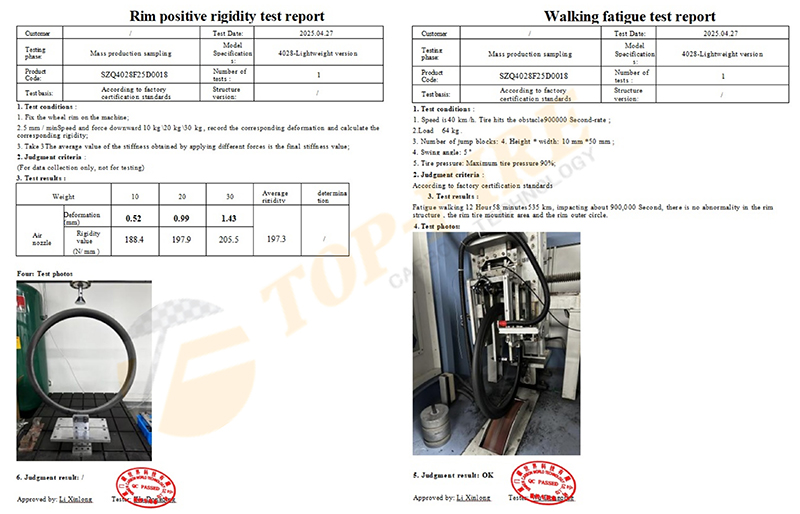

Carbon Road Bike Wheels Performance and Testing

At Top-Fire, every wheel undergoes rigorous physical property tests, including:

Positive & Lateral Rigidity Tests (ISO 4210-7:2014 standard)

Impact & Road Test to simulate real riding conditions

Spoke Hole Tensile Test for long-term durability

Walking Fatigue Test with over 100,000 cycles

Carbon Road Bicycle Wheels Installation & Maintenance Guide

Preparing for Installation

Before installing your carbon road wheels, check that your frame and brakes are compatible. Make sure the hubs match your bike’s axle type. Always use brake pads specifically designed for carbon rims.

Mounting the Wheels

Start by placing the front wheel into the fork dropouts and securing it with a quick-release or thru-axle. For the rear, align the chain on the smallest cog, then slide the wheel into place. Spin each wheel to confirm that it turns freely without rubbing against the frame or brake pads.

Setting Tire Pressure

Carbon rims work best with proper tire pressure. Follow the manufacturer’s limits to avoid damage. Tubeless tires need sealant inside the tire, while clincher tires require tubes. Check the pressure before every ride.

Routine Care and Maintenance

Keep your wheels clean by wiping them down with a soft cloth and mild soap. Avoid harsh chemicals that could damage the resin. Inspect spoke tension regularly and listen for unusual creaks or clicks. If you notice loose spokes, have them adjusted by a professional.

Carbon Road Cycling Wheels Applications

Road Racing

Carbon wheels are often chosen for racing due to their aerodynamic shape and lightweight design. Deeper rims help cut through the wind, giving riders an edge during fast group rides and sprints.

Endurance and Long-Distance Riding

For long days on the bike, comfort and efficiency matter most. Carbon wheels absorb small road vibrations better than alloy wheels. This makes them easier on the body during centuries or multi-day events. The lower rolling resistance also helps conserve energy over long distances.

Climbing and Hilly Terrain

Lightweight carbon rims are well-suited for steep climbs. They reduce the total weight of the bike, which makes it easier to maintain rhythm when the road points upward. Riders who spend time in the mountains often prefer shallower rim depths for improved control and reduced crosswind impact.

Time Trials and Triathlons

In time trials and triathlons, every second counts. Deep-section carbon wheels provide excellent aerodynamic efficiency, helping riders maintain speed with less effort.

Everyday Training

Not every ride is a race. Many cyclists use carbon wheels in daily training to enjoy the same benefits they rely on during competition. With proper care, these wheels hold up well against regular use and add confidence to everyday riding.

Why Choose Top-Fire Carbon Fiber Road Bike Wheels

Focus on Quality

Top-Fire wheels are made with high-grade carbon fiber and strict production standards. Each rim goes through a careful layup process, precise molding, and multiple rounds of testing. This ensures the wheels deliver consistent performance and can handle the demands of both training and racing.

Balanced Performance

These wheels are designed to be light without losing strength. Riders notice faster acceleration, better climbing ability, and steady handling in corners. The aerodynamic rim profiles also help maintain speed on flat roads. The balance between weight, stiffness, and comfort makes them versatile for different riding styles.

Tested and Trusted

Every wheel is checked for impact strength, walking fatigue test report, and rim positive rigidity test report. This testing process makes sure they hold up under real-world riding conditions. Riders can count on the wheels for durability, whether on smooth race courses or rougher local roads.

Options for Different Riders

Top-Fire offers wheels in various rim depths and hub choices, so cyclists can pick what matches their needs. From everyday training to competitive racing, there is a setup that fits. Riders also have the option of custom designs, making the wheels a better match for personal preference.

Road Bike with Carbon Wheels Customization Options

Rim Depth Choices

Riders can choose from different rim depths depending on their needs. Shallow rims, such as 35–40mm, are light and easy to handle on climbs. Mid-depth rims, around 50mm, balance speed and stability. Deep rims, like 60mm or more, are best for flat roads and racing.

Brake System Options

Carbon wheels come in both rim brake and disc brake versions. Rim brake wheels are lighter, while disc brake wheels provide stronger stopping power in all weather. The choice depends on the rider’s frame and riding style.

Hub and Spoke Selection

Hubs influence the smoothness of a wheel's rolling motion and the speed of its engagement. Riders can choose from a variety of hub designs, ranging from lightweight to high-performance. We offer both custom hubs and DT hubs. Spokes are also important, and we offer straight-pull or J-bend spokes, each with varying degrees of strength and durability.

TD Hubs

Self-Produced Hubs

Some cyclists prefer a clean matte look, while others want glossy finishes or custom decals. Personalized graphics and logos make the wheels stand out and can match the bike’s color scheme.

Tubeless or Clincher Setup

Many modern carbon wheels are tubeless-ready, giving riders lower rolling resistance and fewer flats. Others may prefer the classic clincher setup for easier tire changes. Both setups are supported, depending on preference.

Carbon Vs Aluminum Road Bike Wheels

Feature

Carbon Wheels

Aluminum Wheels

Weight

Lighter, helps with climbing and acceleration

Heavier, but still durable for daily use

Aerodynamics

Deep rim profiles improve speed on flat roads

Less aerodynamic, usually shallower rims

Comfort

Absorbs road vibrations better

Stiffer ride, less vibration dampening

Durability

Strong but can crack under heavy impact

More resistant to dents and everyday bumps

Braking

Needs special brake pads for rim brakes

Works well with standard brake pads

Price

Higher cost due to materials and process

More affordable and widely available

Best For

Racing, climbing, and performance riding

Training, commuting, and budget-friendly use

Carbon Road Bike Wheelset R4528sl Self-Produced Hubs

FAQ

Q: Are Chinese carbon road bike wheels reliable for daily riding?

A: Yes. Many Chinese carbon road bike wheels are made with high-quality materials and advanced molding processes. When bought from a trusted brand, they can perform just as well as models from bigger names.

Q: What is the benefit of using carbon road wheels 700c?

A: Carbon road wheels 700c are the standard size for most modern road bikes. They roll smoothly, maintain speed well, and are available in different rim depths to suit climbing, racing, or training.

Q: Are carbon road wheels clincher or tubeless better?

A: Carbon road wheels with clincher tires are easy to set up and make tire changes simple. Tubeless options, on the other hand, can reduce flats and lower rolling resistance. The best choice depends on your riding style.

Q: Why do cyclists choose carbon road bike disc wheels?

A: Carbon road bike disc wheels provide stronger and more consistent braking, especially in wet conditions. They also allow for wider tires, which improves comfort and grip on rough roads.

Q: How do I make carbon road wheels last longer?

A: Keep them clean, check spoke tension, and use the right brake pads for carbon rims. Avoid hitting potholes at high speed, and your wheels will stay strong for years.

Previous:

30mm Width and 60mm Depth Carbon Road Bike Wheels 700C DT Swiss 350 HubNext:

Top-Fire 700C Carbon Wheelset For Road Bike DT Swiss 350 HubIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

New Full Suspension Bafang M620 Motor Carbon Ebike Framest For MTB And Fat Bike Read More

Fully Internal Cable Routing Suspension Electric MTB Frame Read More

Carbon Gravel Ebike Frame With FSA Hub Motor And Battery Read More

Carbon Cyclocross Disc Gravel Bike Frame For BB T47 Read More

Top-Fire 27.5er 29er 27mm Width 25mm Depth Hookless Mtb Carbon Rims For XC Read More

New Style 700C Carbon Clincher Rims 58mm Depth Wavy Line Design Read More

Copyright © 2026 Top-Fire Carbon Technology Co., Ltd. All Rights Reserved. Power by

IPv6 network supported