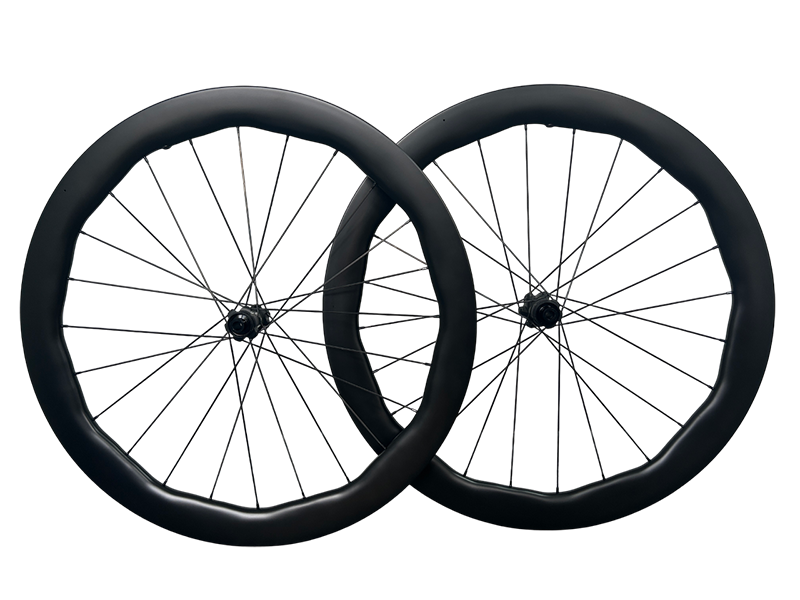

This carbon fiber road wheelset is designed for high-speed cruising and climbing efficiency, balancing lightweight and aerodynamic performance. Crafted from high-modulus carbon fiber, it provides rigidity while significantly reducing overall weight, resulting in quicker acceleration and easier climbing. The rounded rim cross-section optimizes wind resistance, ensuring stable handling in crosswinds.

Item NO.:

R5156-2Payment:

Paypal, Bank Transfer, West UnionProduct Origin:

Xiamen,ChinaColor:

UD/3K/12K(Customized Painting Acceptable)Shipping Port:

XIAMENTop-Fire 700C Carbon Wheelset For Road Bike

Carbon Road Bike Wheels Feature

*All of our carbon road rims fit this lightweight hub.

Carbon Road Wheels 700c Specification

Model

R5156-2

Weight

Front Wheel Weight: 765.9g

Rear Wheel Weight: 890.7g

Rim Size

Drills: 24/24 Holes

Outer Width: 30.8mm

Inner Width: 23.4mm

Tire Compatibility

Clincher/ Tubeless

Recommended Tire Size

25-28C

Chossen Hub

DT 370

Perrin:Ceramics

Freehub Body:Planetary gear(Shimano)

Spacing:Front: 12*100 mm Rear:12*142mm

Spoke Count

Front: 24 Rear:24

Spoke Pattern

Front: 2X 1:1 Rear: 2X 1:1

Max Spoke Tension

>450kgf

Rim Material

Toray T700 + T800 Carbon Fibers

Spoke Material

SAPIM cx-leader

Disc brake/rim brake

Disc brake

Warranty

18 months

Packing Size

850*650*200mm(Carton)

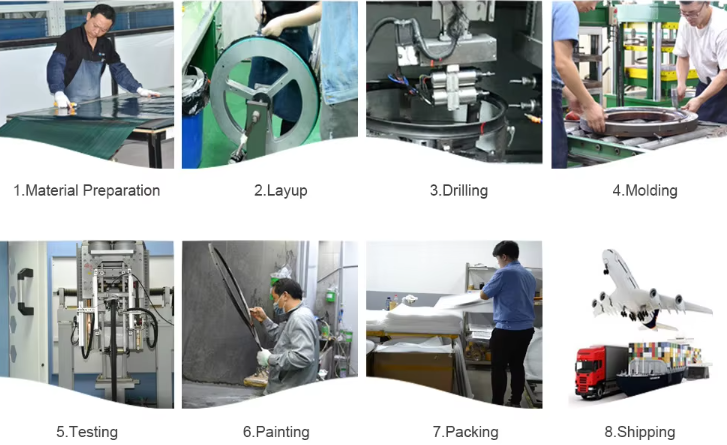

Carbon Road Wheels Manufacturing Process

Material Preparation

The process begins with selecting premium carbon fiber sheets. Each sheet is inspected for consistency, thickness, and fiber alignment before being precisely cut to size. This step ensures the structural integrity and performance of the final wheel.

Drilling

After preliminary shaping, precision drilling machines create accurate spoke holes and valve holes. This step demands high accuracy to ensure perfect spoke alignment and long-term durability under riding stress.

Molding

The mold is closed and heated under pressure. This bonds the resin and fibers together, creating the rim’s solid structure.The layered carbon is placed into a high-temperature, high-pressure mold. This molding process compresses the fibers and cures the resin, forming the wheel’s final structure while maximizing strength and minimizing weight.

Testing

Each molded rim undergoes rigorous quality checks. Dimensional accuracy, roundness, and structural integrity are tested, by load and impact tests to confirm safety and performance.

Painting

A protective coating or custom paint is applied, giving the wheel its final look and extra protection against the elements.After passing tests, rims enter the painting and finishing stage. Here, protective coatings and custom graphics are applied. This not only enhances the aesthetic appeal but also provides UV and weather resistance.

QC Test

Every rim undergoes strict dimensional, strength, and balance testing.Wheels are carefully packed using protective foam and custom-fit boxes to prevent any damage during transport. This ensures they arrive to customers in perfect condition.

Shipping

Finished carbon road wheels are shipped worldwide via air, sea, or land logistics, ready to deliver top-tier performance to cyclists across the globe.

Carbon Road Bicycle Wheels Compatibility & Installation

Compatibility

Before choosing a wheel, check that the hub type is compatible with your bike's drivetrain. Most carbon road wheels come with a Shimano, SRAM, or DT freehub hub. You should also check your braking system; rim brake wheels have a brake rim, while disc brake wheels have mounting points for the disc rotors. Tire compatibility is also important; some wheels are compatible with clincher, tubular, or tubeless tires.

Installation

First, secure the correct cassette to the freehub. Install the tire and inner tube, and if using tubeless tires, apply sealant. Install the wheel onto the chainstay, ensuring it is securely seated and evenly aligned. Tighten the quick-release or thru-axle, but do not overtighten. Before riding, spin the wheel to check for smooth rotation and proper clearance.

Carbon Wheels vs Alloy Wheels

Feature

Carbon Wheels

Alloy Wheels

Weight

Lighter, making climbs and acceleration easier.

Heavier, which can slow you down on hills.

Stiffness

Very stiff, improving power transfer.

More flexible, which can feel softer but less efficient.

Aerodynamics

Better shapes for reduced drag.

Less aerodynamic, especially at deeper rim profiles.

Durability

Strong but can be damaged by sharp impacts.

More resistant to minor impacts but can dent.

Cost

Higher price due to advanced materials.

More affordable for most riders.

Carbon Fiber Road Bike Wheels Custom

Custom Rim Depth and Width

You can choose the rim depth and width based on your riding style. Shallower rims are lighter and easier to accelerate, while deeper rims improve aerodynamics. Pick the right size to match your performance goals and bike frame clearance.

Spoke Count and Pattern

You can customize the number of spokes and the lacing pattern. Fewer spokes reduce weight, while more spokes increase durability. Choose a pattern that balances strength and ride comfort for your needs.

Hub Options

You have two hub options for your wheelset:

TD Hubs – High-quality, widely compatible hubs for reliable performance.

Custom Hubs Produced by Us, Fully designed by our factory for optimized stiffness, weight, and compatibility with your bike. You can choose the hub style and bearing type according to your preference.

DT Hubs

Own Hub

Logo and Design Options

Personalize your wheels with custom logos, colors, or decals. This makes your bike unique and matches your style. You can select subtle designs for a professional look or bold graphics for a standout appearance.

Tubeless or Clincher Setup

Decide whether you want a tubeless-ready wheelset or a standard clincher setup. Tubeless wheels offer lower rolling resistance and fewer flats, while clincher wheels are easier to install and maintain. Your choice depends on your preferred riding experience.

Road Bike With Carbon Wheels Maintenance & Care Guide

Cleaning Your Wheels

Keep your carbon wheels clean to maintain performance and durability. Use a soft brush or cloth with mild soap and water. Avoid harsh chemicals that can damage the carbon finish. Rinse thoroughly and dry with a soft towel.

Brake Surface Care

If you have rim brake wheels, check the brake track regularly. Remove any debris or metal shavings to prevent wear. Make sure your brake pads are compatible with carbon rims to avoid overheating or surface damage.

Tire and Spoke Checks

Inspect tires for cuts, wear, or punctures.

Check spoke tension occasionally to keep the wheel true.

Tighten any loose bolts or quick-release skewers.

Storage Tips

Store your bike in a dry, shaded area to avoid UV damage or moisture buildup. Avoid leaning your bike on the wheels for long periods. Consider using a bike stand to keep the wheels off the ground.

700C Carbon Wheelset For Road Bike R5156-2 DT Hub

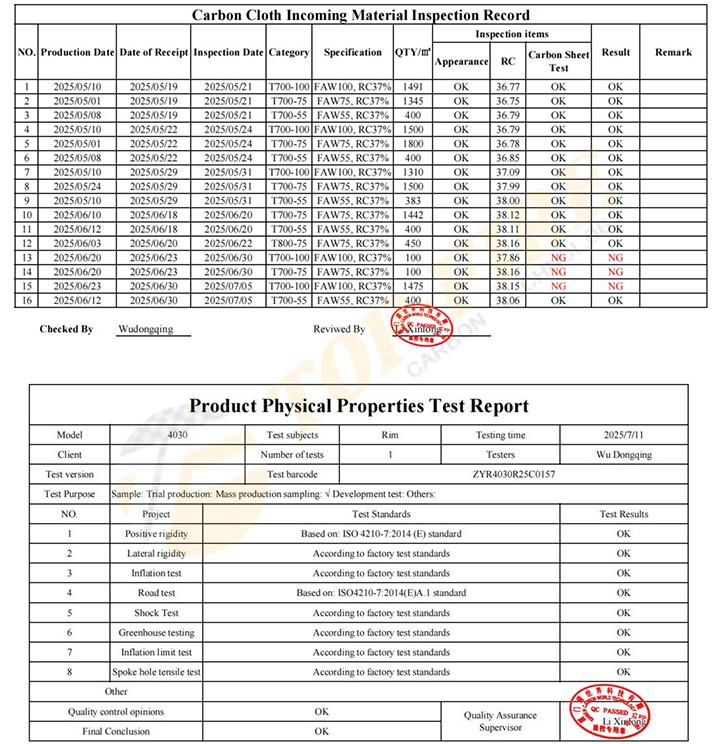

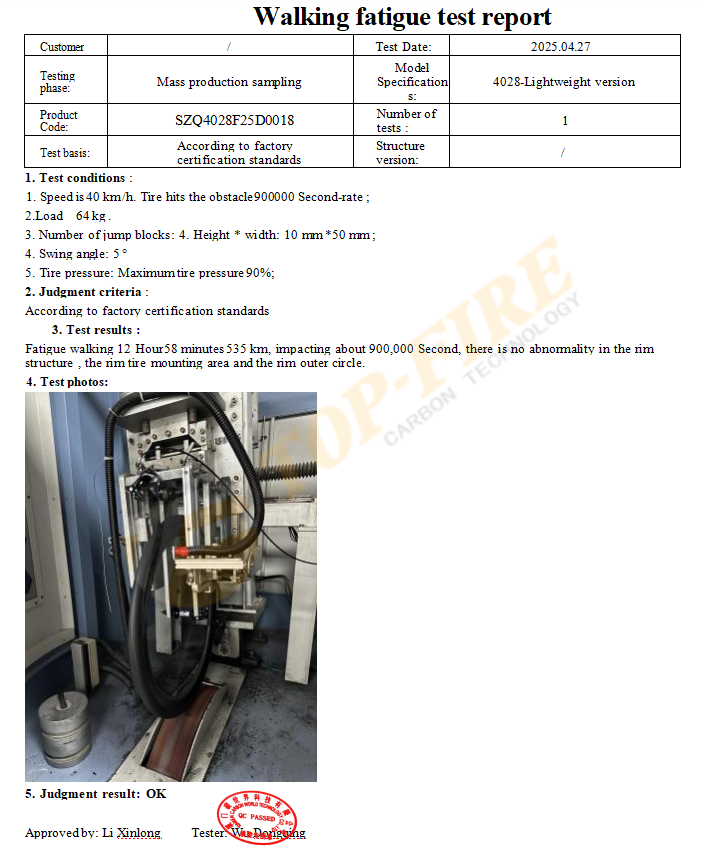

Test Report

Every carbon fiber wheel we produce undergoes rigorous, internationally recognized testing to ensure safety, performance, and durability.

Walking Fatigue Test

Our carbon wheel completed a 12-hour, 58-minute continuous fatigue test covering 535 km, simulating approximately 900,000 obstacle impacts at a speed of 40 km/h under a 64 kg load. The result: No structural abnormalities in the rim mounting area or the outer rim circle. This confirms exceptional fatigue resistance for real-world riding conditions.

Carbon Cloth Incoming Material Inspection

TOP-Fire strictly inspects every batch of carbon cloth before production. Tests cover appearance, fiber uniformity, resin content, and carbon sheet thickness. Only materials meeting our factory certification standards move forward to manufacturing, ensuring consistent quality from the source.

Product Physical Properties Test

Carbon wheels passed all critical tests, including:

Positive & lateral rigidity (ISO 4210-7:2014 standards)

Inflation & inflation limit tests

Road and shock resistance

Spoke hole tensile strength

Greenhouse environmental testing for temperature and humidity resistance

Conclusion: All results passed, with every parameter meeting or exceeding international and factory standards.

Carbon Road Bike Wheelset FAQ

1. How long do carbon road wheels 700C last?

The lifespan of carbon fiber road bike wheels 700c depends on your riding style and maintenance. With proper care, they can last for many years. Avoid hard impacts like potholes or curbs, and inspect the rims regularly for cracks.

2. Are carbon wheels suitable for all road bikes?

Carbon wheels fit most road bikes, but you should check hub spacing and brake compatibility. Make sure the wheel size matches your frame and fork clearance.

3. Can I repair a damaged carbon rim?

Minor cosmetic scratches are usually not a problem, but deep cracks or structural damage require professional inspection. Do not ride on a damaged rim, as it can be unsafe.

4. How do I prevent flats with carbon wheels?

Use the right tire pressure for your weight and conditions.

Consider tubeless setups with sealant for fewer punctures.

Check tires regularly for cuts or embedded debris.

5. Do carbon wheels improve performance?

Yes, they reduce rotational weight and improve stiffness, which helps with acceleration and climbing. They also allow for aerodynamic rim shapes that make your ride more efficient.

Previous:

Top-Fire 700C Fastest Carbon Road Bike WheelsNext:

Top-Fire 700C 20mm Width 20mm Depth Lightweight Hub Tubular Rim Brake Carbon Wheelset For Road BikeIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

New Products

New Full Suspension Bafang M620 Motor Carbon Ebike Framest For MTB And Fat Bike Read More

Fully Internal Cable Routing Suspension Electric MTB Frame Read More

Carbon Gravel Ebike Frame With FSA Hub Motor And Battery Read More

Carbon Cyclocross Disc Gravel Bike Frame For BB T47 Read More

Top-Fire 27.5er 29er 27mm Width 25mm Depth Hookless Mtb Carbon Rims For XC Read More

New Style 700C Carbon Clincher Rims 58mm Depth Wavy Line Design Read More

Copyright © 2026 Top-Fire Carbon Technology Co., Ltd. All Rights Reserved. Power by

IPv6 network supported